Wheel Chock Trolley H2WC-7

Price 3625 INR/ Number

Wheel Chock Trolley H2WC-7 Specification

- Color

- Red

- Product Type

- KTI MS Trolley Wheel Chock

- Weight

- 8 kg

- Function

- Other

- Size

- W1000XH800MM

- Feature

- Heavy-duty steel construction with powder coating

- Power Needed

- No external power needed

- Usage

- Designed for storing and transporting wheel chocks safely in workshop or industrial environments

- Handle Type

- Push handle with ergonomic grip

- Applications

- Railway yards, garages, industrial workshops, airports

- Mobility

- Fitted with four wheels for easy transportation

- Chock Storage Capacity

- Holds up to 7 standard chocks

- Material

- Mild Steel (MS)

- Finish

- Durable powder-coated surface for corrosion resistance

Wheel Chock Trolley H2WC-7 Trade Information

- Minimum Order Quantity

- 10 Number

- Delivery Time

- 8 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

- Certifications

- yes

About Wheel Chock Trolley H2WC-7

Height 800 mm

maximum width approx 40 inch

weight approx 78 kg pipe 40 mm

Warranty NA

Available METAL RUBBER MATERIAL

size 12 kg 10 kg 65 kg 55 kg 3 kg rubber wheel chock

unbrakable wheel chock

metal 26 to 3 kg

Engineered for Safe and Efficient Chock Handling

Constructed with robust mild steel, the Wheel Chock Trolley H2WC-7 features a powder-coated finish to withstand harsh environments and prevent corrosion. Its four-wheel design and ergonomic handle simplify navigation, ensuring secure transportation of wheel chocks within busy workshop or industrial settings.

Streamlined Operations for Various Professional Settings

Designed to meet the storage needs of railway yards, airports, garages, and workshops, this trolley optimizes wheel chock organization and accessibility. Holding up to seven standard chocks, it supports efficient workflows while contributing to a safer, clutter-free environment.

FAQs of Wheel Chock Trolley H2WC-7:

Q: How do I use the Wheel Chock Trolley H2WC-7 in an industrial workshop?

A: To use the trolley, simply place up to seven standard wheel chocks in the designated storage slots, then push the trolley using its ergonomic handle. Its four wheels facilitate smooth movement across various workshop surfaces, allowing you to transport chocks safely and efficiently as needed.Q: What benefits does the powder-coated mild steel construction offer?

A: Powder-coated mild steel provides enhanced corrosion resistance and durability. This feature ensures that the trolley maintains its structural integrity and appearance, even in demanding environments such as railway yards or airports.Q: Where is the Wheel Chock Trolley H2WC-7 commonly utilized?

A: The trolley is widely used in railway yards, industrial workshops, garages, airports, and similar locations where wheel chocks are necessary for safety and organization.Q: When should wheel chocks be stored and transported using this trolley?

A: Wheel chocks should be stored and transported on the trolley when not in use, during maintenance operations, or when relocating chocks within a facility. This practice maintains workplace safety and minimizes the chances of misplaced or damaged equipment.Q: What process should be followed for cleaning and maintaining the trolley?

A: Regularly wipe down the trolley with a damp cloth to remove dust or debris. Inspect its wheels and handle for wear and tear, and check the powder-coated surface for any chips or scratches to ensure optimal longevity.Q: Is any external power required to operate the Wheel Chock Trolley H2WC-7?

A: No external power is needed. The trolley is designed for manual operation, relying on its push handle and smoothly rolling wheels for easy mobility.Q: What advantages does holding multiple wheel chocks on a single trolley provide?

A: By accommodating up to seven chocks, the trolley simplifies the process of collecting, storing, and transporting wheel chocks, promoting both efficiency and organization within busy industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Metal Expandable Marrier Category

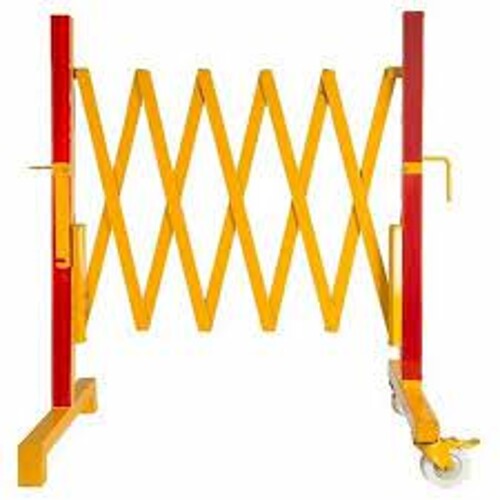

Metal Expandable Barrier -6 Meter

Price 10360 INR / Number

Minimum Order Quantity : 1 Number

Power Needed : No

Function : Manual

Material : metal

Color : Yellow

Water Filled Road Barrier 1125x400x400 MM(Nilkamal Red/yellow)

Price 2437 INR / Number

Minimum Order Quantity : 1 Number

Power Needed : No

Function : Manual

Material : Plastic

Color : Red

Water Filled Road Barrier 1500x410x1000 mm (Fortntier)

Price 5070 INR / Number

Minimum Order Quantity : 1 Number

Power Needed : No

Function : Manual

Material : Plastic

Color : Red

Plastic Expandable Barrier with wheels 4 Meter

Price 24500 INR / Piece

Minimum Order Quantity : 1 Meter

Power Needed : Other, None, manual operation

Function : Other, Temporary barrier for crowd control, area segregation and traffic management

We mainly cater to clients from Gujarat.

Send Inquiry

Send Inquiry

Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese