Dock Leveler

Price 5000 INR/ Number

Dock Leveler Specification

- Connectivity Type

- Wired hydraulic control system

- Sensor Type

- Limit switch sensors for precise position control

- Technology

- Electro-hydraulic system

- Special Features

- Heavy-duty steel construction, Electro-hydraulic operation, Anti-slip surface, Adjustable platform height, Safety lip for enhanced security

- Remote Control

- Available optional remote control for platform operation

- Application

- Loading and unloading goods at docks, warehouses, logistic centers

- Power Supply

- Three-phase AC electric supply

- Mounting Type

- Pit mounted installation

- Cycle Time

- Raising and lowering in less than 50 seconds

- Control Panel

- Weatherproof electrical control panel

- Lip Length

- Standard length 400 mm to 500 mm

- Platform Size

- Customizable dimensions, standard width up to 2100 mm

- Surface Coating

- Anti-corrosive powder coating

- Operation Temperature

- -20°C to +50°C

- Load Capacity

- Rated capacity from 6000 kg to 9000 kg

- Safety Features

- Emergency stop function, side safety skirts, maintenance struts

- Compliance

- Conforms to international docking equipment standards

Dock Leveler Trade Information

- Minimum Order Quantity

- 1 Number

- FOB Port

- Ex - Office

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 50 Per Year

- Delivery Time

- 5 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Dock Leveler

Dock LevelerStatic Load 9 Tons

(w)2377mm x

(l)2895mm x

(h)585mm

CE Certified As Per European

Standard

BS EN 1398:2009(E)

Push Button - 1 No

Dock levelers are made of heavy duty Corrosion-resistant steel.

2 Anti skid chequered Platform to avoid any accidents.

3 Dock levelers are integrated with safety valve to prevent any accidents incase of breakdown of oil-hydraulic pipe.

4 Dock levelers Lip is designed to suit various truck sizes.

5 Specially designed Power Pack for heavy use.

6 Two hydraulic cylinders for platform movement and one for Lip plate movement

7 Optional Accessories: Traffic Light, Push Button with Mushroom type Stop Button.

8 CE Certified As Per European Standard - EN 1398 : 2009 (E)

II) . Technical Specification

1 Standard Capacity - Static load 9 tons & dynamic load 6 tons

2 Platform Size - 2377 mm(W) x 2895 mm(L)

3 Lip Size - 2377 mm(W) x 400mm(L)

4 Shut Height - 585mm(H)

5 Working Length - 2377 x 3295 mm(L)

6 Overall Size - 2377 mm(W) x 3295 mm(L)

7 Travel Range ( Above and Below) - + 300 mm / -180 mm from FFl

8 Platform Surface - Robust construction with antiskid MS chequered plate 6 mm thk.

9 Swinging Lip Plate - Plain MS Sheet 12mm thick

10 Swinging Hinge - Specially designed swinging hinge consists of MS Bright Bar hinge pin rod

11 Hinge Pin - Specially designed MS Bright Bar Hinge pin for Swinging of Lip and Platform

12 Clear Pit Dimensions - 2427 mm(W) x 2895 mm(L) x 590mm(H)

13 Loading Platform Height from Road - 1250 mm, 1400 mm (as per clients requirement)

14 Cylinders - Hydraulic single acting cylinders 2 Nos for platform lifting and 1 no for lip lifting

15 Power Pack - Specially designed Power pack for dock leveller

16 Control Panel - Compact Control Panel consist of single push Button

17 Surface Finish - Deck assembly & front cover Grey (RAL 7040) ; Lip plate, Deck side plate & accessories Melon Yellow

(RAL1028)

18 Type of Lip Plate - Segmented Lip

19 Rubber Bumper - 1 Pair of rubber bumpers

20 Super Rubber Bumper (Optional) - 1 Pair of rubber bumpers

Warranty:- 1 Year

Customizable and Heavy-Duty Design

The dock leveler is designed to accommodate specific platform size requirements. Its heavy-duty steel build supports demanding operations with rated capacities from 6000 kg to 9000 kg and a standard lip length of 400500 mm. This versatile equipment is suitable for a range of logistics environments, ensuring robust performance in extreme temperatures from 20C to +50C.

Advanced Safety and Operation Features

Safety is prioritized with emergency stop functions, side safety skirts, maintenance struts, and a safety lip for enhanced security during loading activities. The electro-hydraulic control and limit switch sensors provide smooth, reliable, and precise movement, managed through a weatherproof control panel or optional remote control for added convenience.

FAQs of Dock Leveler:

Q: How is the dock leveler installed at my facility?

A: The dock leveler is typically pit mounted to ensure secure and stable integration into your loading bay. Professional installation services are recommended to meet safety and compliance standards.Q: What benefits do the adjustable platform height and safety lip provide?

A: The adjustable platform height enables seamless alignment with various truck bed heights, enhancing efficiency. The safety lip provides additional protection by preventing accidental slips, making loading and unloading safer.Q: When should I use the emergency stop function?

A: The emergency stop should be engaged immediately in case of any malfunction or hazardous situation to halt the platforms movement and prevent injury or equipment damage.Q: Where can this dock leveler be used?

A: This dock leveler is ideal for loading docks, warehouses, distribution centers, and logistic facilitiesany environment requiring efficient goods transfer between vehicles and platforms.Q: What is the process for operating the dock leveler?

A: Operation is managed via the weatherproof electrical control panel or an optional remote control. The electro-hydraulic system allows the platform to raise or lower in under 50 seconds for quick cycle times.Q: How does the anti-slip surface and anti-corrosive coating enhance durability and safety?

A: The anti-slip surface minimizes risk of accidents while handling goods, and the anti-corrosive powder coating ensures long-term durability even in harsh environments.Q: Is support available for maintenance and servicing in India?

A: Yes, dealers, distributors, retailers, service providers, and suppliers across India can offer maintenance, technical support, and replacement parts for your dock leveler.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

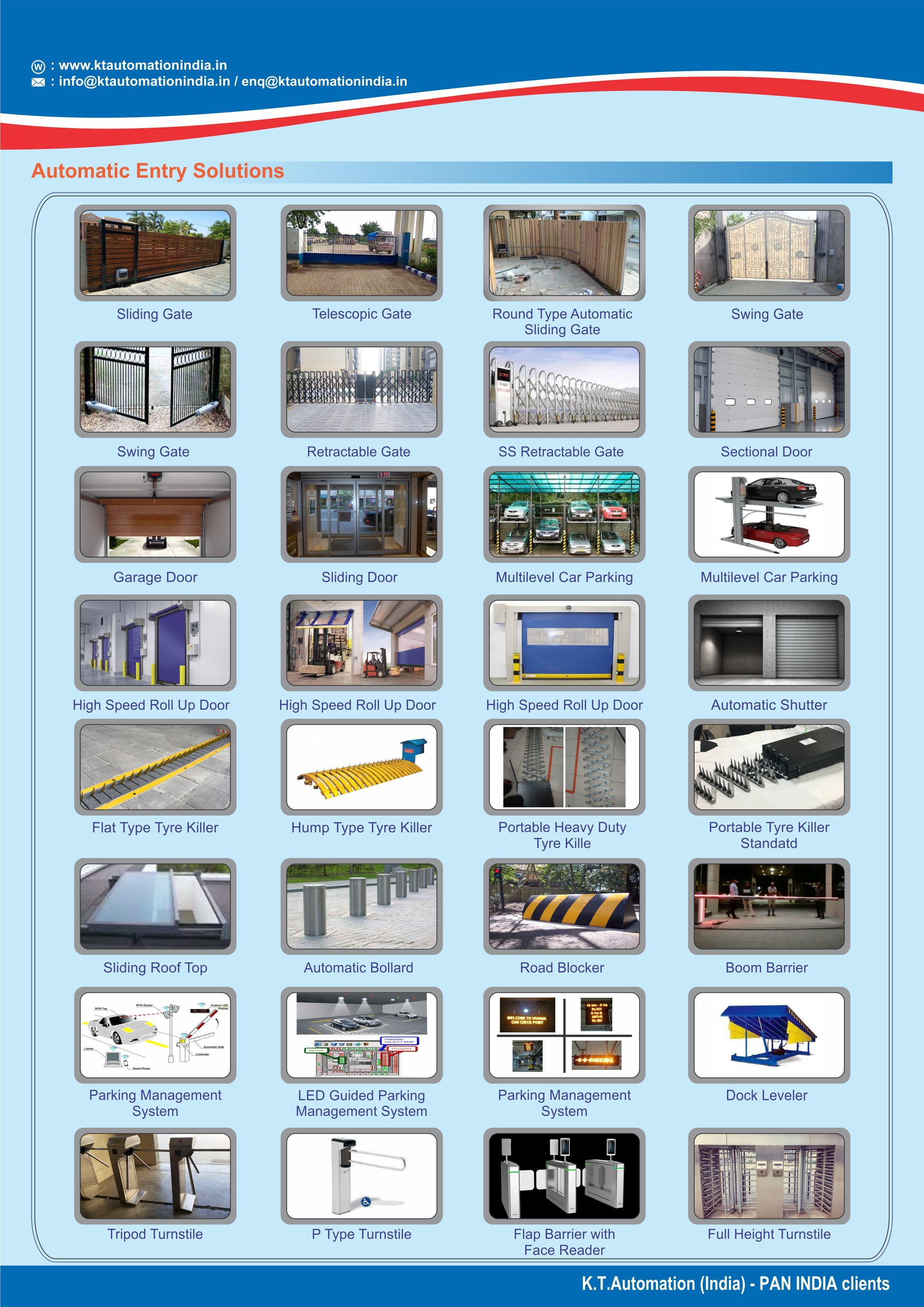

More Products in Automatic Entry Solutions Category

Boom Barrier With LED Up to 5 Meter Swaraj Secutech

Price 73500 INR / Number

Minimum Order Quantity : 1 Number

Material : ALUMINIUM WITH MS/SS

Usage : Automatic Solution

Power Supply : na

Color : YELLOWBLACK

Portable Tyre Killer

Price 19740.0 INR / Unit

Minimum Order Quantity : 1 Unit

Material : aluminium stripe

Usage : Industrial

Color : BLACK

Flap barrier

Price 118800 INR / Piece

Minimum Order Quantity : 1 Number

Material : Acrylic, SUS304 Stainless Steel,

Usage : to restrict the entry

Power Supply : AC 100 ~ 120V/200 ~ 240V, 50/60Hz

Swing Barrier - SBT 2000S

Price 109350 INR / Piece

Minimum Order Quantity : 1 Number

Material : Acrylic, SUS304 Stainless Steel,

Usage : to protect your premises.

We mainly cater to clients from Gujarat.

Send Inquiry

Send Inquiry

Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese